News

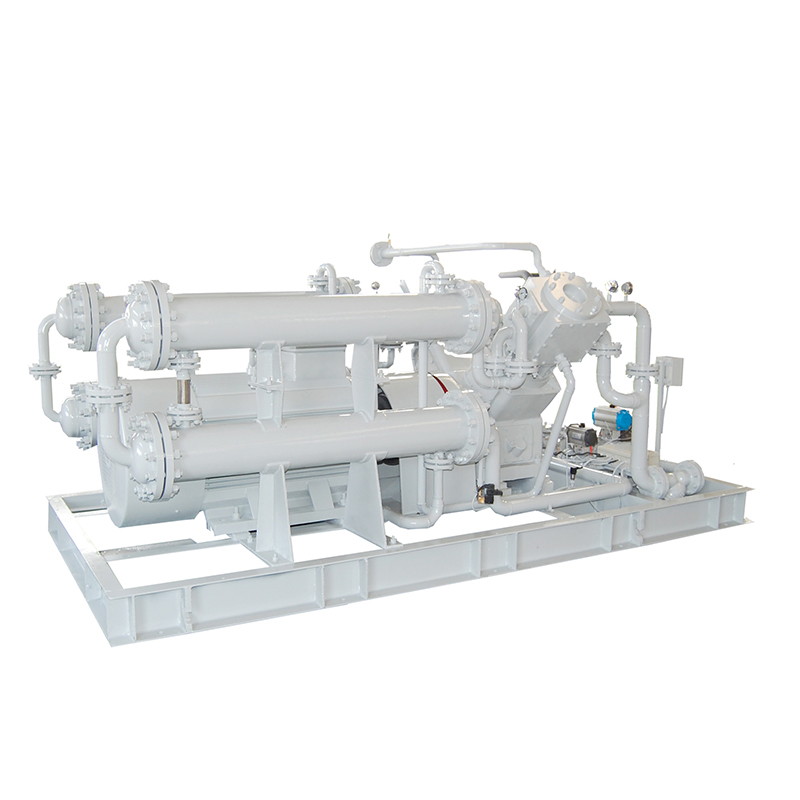

Core use of helium compressor

Helium compressor is a kind of equipment specially used for compressing high-purity helium, and its core uses can be summarized into the following five areas:

1. Low temperature refrigeration and vacuum system

Helium compressor is the key driving equipment of cryogenic pump system or other refrigeration units, which can maintain ultra-low temperature environment (such as near absolute zero) by providing high-purity helium. This kind of application is common in;

Astronomical observation equipment: cooling the infrared detector and other components of the telescope;

Scientific research experiments: such as particle accelerator, cooling of superconducting magnet;

Semiconductor manufacturing: providing vacuum environment for the previous processes such as evaporation, sputtering and ion implantation.

2. Semiconductor and electronic industry

In the field of semiconductors, helium compressors are used;

Maintain high cleanliness vacuum environment to ensure wafer processing accuracy;

Cooperate with gas recovery system to reduce helium waste (because helium is scarce and costly).

3. Cooling of medical equipment

he extremely low boiling point of helium makes it an ideal cooling medium for medical equipment, such as: Magnetic resonance imaging (MRI): cooling the superconducting electromagnet to maintain a stable magnetic field;

CT scanner: Some high-end equipment relies on helium refrigeration technology.

4. Helium recovery and recycling

Because helium resources are scarce and expensive, compressors play an important role in the recovery system.

Re-liquefying helium after leak detection or industrial use by multistage compression (up to 343mpa);

Special helium compressor adopts double seal design to prevent tiny leakage (ordinary breathing air compressor cannot meet the demand).

5. Industrial gas power and special technology

Metal processing: used in quenching process to avoid oxidation and replace oil coolant;

High-precision welding: as a protective gas to prevent weld oxidation;

Deep-sea diving and aerospace: provide a test environment for breathing mixed gas or propulsion system.

Technical classification: According to the pressure demand, helium compressors can be divided into low pressure (100mpa) and other types, and multi-stage compression design can meet the needs of different scenarios.

RELATED NEWS

CATEGORIES

LATEST NEWS

CONTACT US

Name: Zcfii

Mobile:85259581590

Tel:85259581590

Whatsapp:85259581590

Email:zcfii.com@gmail.com

Add:HO KING COMM CTR, 2-16 FAYUEN ST, MONGKOK KOWLOON HONG KONG